AddUp

Revolutionising Aerospace & Defence Through 3D Printing

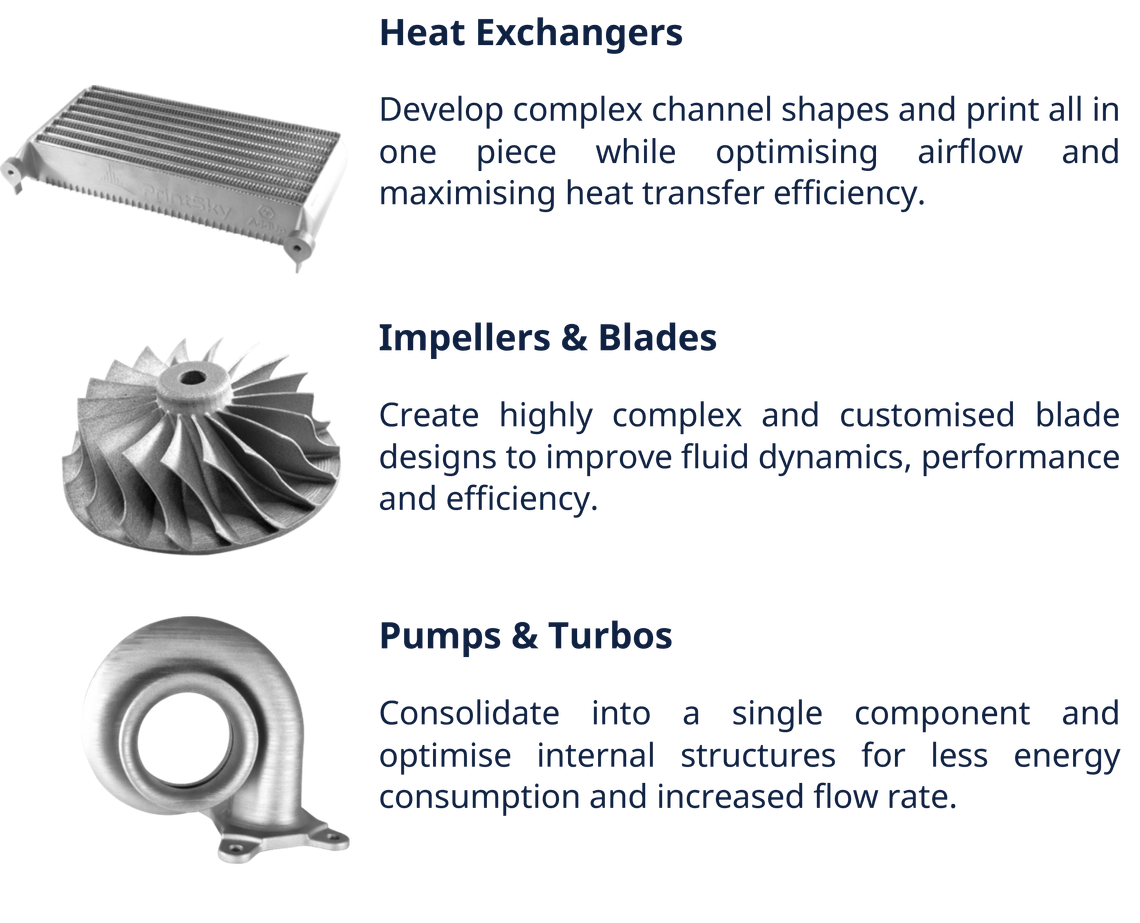

Aerospace components often require intricate and complex shapes that are difficult or impossible to achieve using traditional manufacturing methods.

Additive manufacturing offers clear benefits to the aerospace industry including:

• Improved design

• Reduced weight via topological optimisation

• Enhanced aerodynamics and thermal

• More efficient production processes

The defence sector can face supply chain disruptions due to geopolitical issues or emergencies and benefits from:

• Reduce lead times

• Eliminate the risk for some tooling

• Enables on-demand production

• Produce critical components on or near site

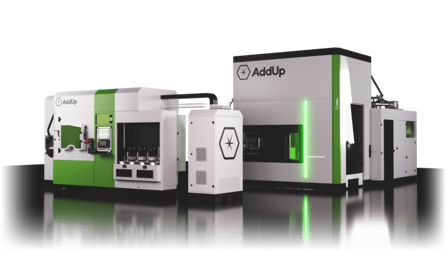

Safer, Cleaner, More Efficient Solutions with High-Performance Metal Additive Manufacturing (AM) Machines

FormUp Range – Powder Bed Fusion

Machines are built to do serial production in a digital manufacturing environment–and to do it well - without compromising quality or productivity.

Best-in-class surface finish

Compatible with both standard and fine powders

High-quality, complex parts with minimal support structures

Designed to meet an OEE level demanded for serial production

The most advanced technology to ensure operator safety

An open platform to develop manufacturing recipes based on your application

Machines built for:

PRECISION – Accuracy, industry leading surface finish

PRODUCTIVITY - Reliable and repeatable with high throughput

SAFETY - Protection of people and assets

BeAM Range – Directed Energy Deposition

Machines are designed for industrial production and are equipped with in-house designed and developed nozzles to optimise precision and productivity.

Optimal for near net shape manufacturing

Suitable for use with reactive powders

Useful for repairing worn or deteriorated parts

Modify the geometry of an existing part with feature addition

Ability to create new materials from multiple metals

Available in compact and large-format models

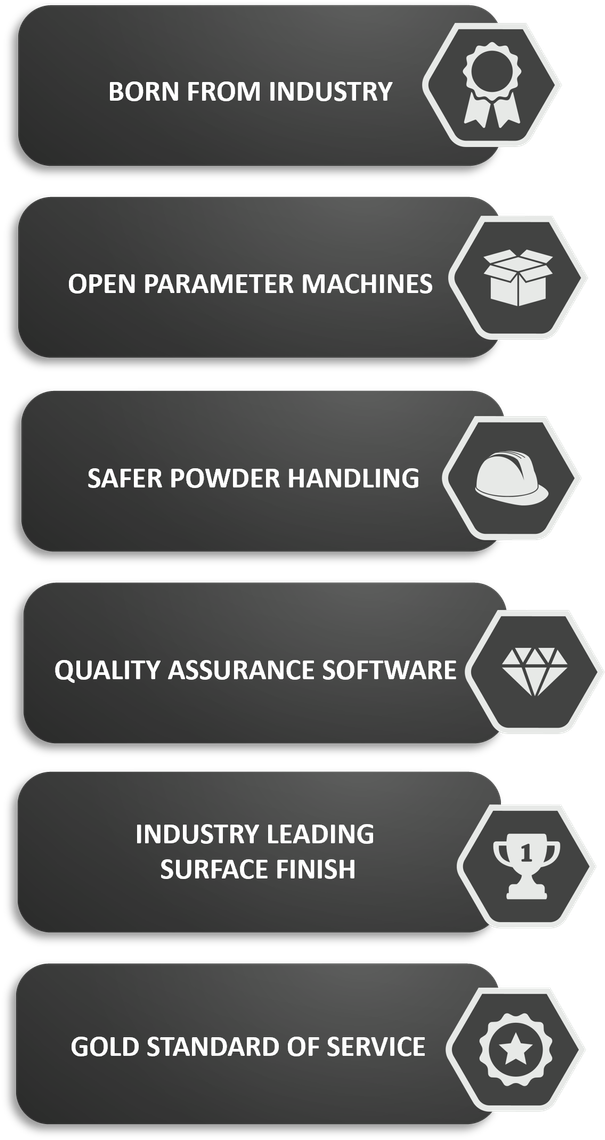

Rooted in Industry, Pioneering the Future of Additive Manufacturing